Boosting Harvest Efficiency: New Seeders Designed for Large-Scale Farms

Across the globe, agriculture is evolving at an unprecedented pace. Farmers managing thousands of hectares face increasing pressure to maximize productivity, reduce labor costs, and meet sustainability targets. In response, manufacturers are unveiling new-generation seeders specifically engineered for large-scale farms. These innovative machines combine cutting-edge technology with robust construction to deliver higher planting accuracy, speed, and cost-effectiveness.

Why Large Farms Need Specialized Seeders

Traditional seeding equipment often struggles to meet the demands of vast, modern operations. Larger farms require machines that can cover more ground quickly without compromising seed placement or depth. The latest large-scale seeders offer wider working widths, bigger seed hoppers, and sophisticated control systems to ensure uniform planting across massive fields.

By investing in specialized seeders, large farms can reduce passes over the field, cut fuel and labor costs, and create optimal conditions for crop emergence and growth.

Key Features of the New-Generation Seeders

Wider Coverage: Today’s machines feature working widths exceeding 15 meters, allowing farmers to plant more hectares per hour.

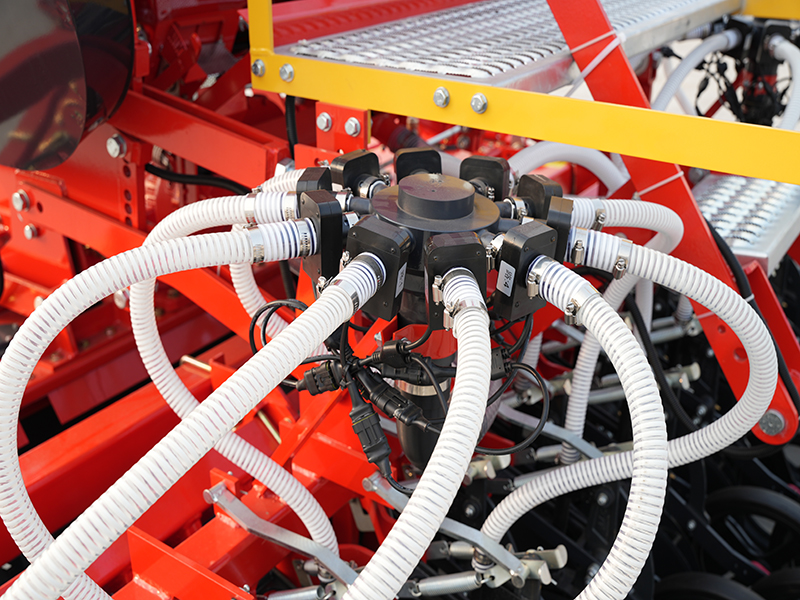

Precision Planting Technology: Advanced metering systems, GPS guidance, and variable-rate controls ensure seeds are placed at the correct depth and spacing—even in challenging soil conditions.

Durable Construction: Heavy-duty frames and high-quality components enable seeders to handle continuous use in tough field environments.

User-Friendly Operation: Touchscreen interfaces and remote diagnostics simplify calibration and maintenance, reducing downtime.

Sustainability Benefits: Accurate seed placement minimizes wastage, reduces soil disturbance, and improves input efficiency.

Q&A: Common Questions About Large-Scale Farm Seeders

Q1: How do precision seeders improve crop yields?

A1: By controlling seed depth and spacing, precision seeders create uniform plant stands, which leads to better germination, improved growth, and ultimately higher yields.

Q2: Are these new seeders compatible with existing tractors?

A2: Many models are designed to attach to standard high-horsepower tractors. Manufacturers often offer compatibility charts or customization options to match different tractor brands.

Q3: Can variable-rate seeding save on input costs?

A3: Yes. Variable-rate technology uses field maps to adjust seeding rates on the go, ensuring optimal planting density while reducing seed waste and maximizing return on investment.

Q4: How is maintenance handled for such large machines?

A4: Modern seeders feature modular components, easy-access service points, and sometimes remote monitoring to predict maintenance needs before breakdowns occur.

Q5: Are the new seeders environmentally friendly?

A5: Precision placement reduces over-seeding, soil compaction, and chemical use, making them more sustainable compared to conventional models.

Technology Behind the Efficiency

Modern seeders integrate GPS, auto-steering, and data analytics. Farmers can monitor real-time performance on tablets or in tractor cabins, adjusting settings instantly to match field conditions. Some models also link to farm management software, creating digital records of planting operations for better decision-making.

Sensors detect soil moisture, texture, and organic matter, automatically adapting seeding rates to micro-variations within the field. This level of control was once only possible in research environments but is now accessible to commercial growers worldwide.

Case Studies: Large Farms Achieve More with New Seeders

In North America, a 5,000-hectare wheat operation reported a 12% yield increase after adopting precision seeders. The farmer credited accurate seed placement and reduced overlap for the improvement. In South America, a soybean producer cut planting time in half by using a 24-row high-speed seeder equipped with GPS guidance and variable-rate controls.

Advantages for Farmers and Agribusinesses

Higher Productivity: Cover more hectares in less time. Lower Operating Costs: Save on fuel, labor, and seed. Improved Yields: Achieve uniform plant populations and healthier crops. Better Resource Management: Use data-driven insights to plan inputs. Sustainable Practices: Reduce soil compaction and waste.

Overcoming Challenges in Large-Scale Planting

Operating large seeders requires careful planning. Transporting wide machines between fields can be challenging, but many models feature folding mechanisms for easier road travel. Training operators on calibration and technology use is also crucial. Manufacturers now provide online tutorials, on-site training, and customer support to ensure smooth adoption.

The Future of Seeding Technology

Looking ahead, we can expect even more automation and connectivity. Self-driving seeders, integration with drones, and AI-powered decision-making are on the horizon. These innovations will help farmers further optimize inputs, reduce environmental impact, and increase profitability.

Hybrid systems combining seeders with real-time soil analysis tools or robotic row cleaners may soon become mainstream, making large-scale planting even more efficient.

Conclusion

For large farms aiming to boost productivity and sustainability, new-generation seeders represent a transformative investment. By combining wider coverage, precision planting, and user-friendly technology, these machines help farmers plant faster, grow stronger crops, and achieve higher profits. As innovation continues, the gap between traditional and precision agriculture will widen, making advanced seeders a must-have for competitive agribusinesses.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).