Cutting System Innovations Boost Efficiency in Large-Scale Mowing Operations

In today’s agricultural and landscaping industries, efficiency and precision are not just advantages—they are necessities. As demand for sustainable land management and large-scale mowing grows across Europe, North America, and the Middle East, cutting system innovations are reshaping the way mowing equipment performs. From intelligent blade systems to AI-assisted operations, the evolution of cutting technology is setting new benchmarks in power, speed, and sustainability.

The modern mowing industry has come a long way from traditional rotary blades. Over the past decade, advancements in mechanical engineering, materials science, and smart control systems have led to the creation of cutting systems that are not only more efficient but also more durable and environmentally friendly. Manufacturers are integrating high-carbon steel blades, aerodynamic decks, and variable-speed cutting controls. These systems optimize power usage, reduce wear and tear, and ensure uniform grass cutting even on rough terrain.

Smart Sensors and Automation in Mowing Operations

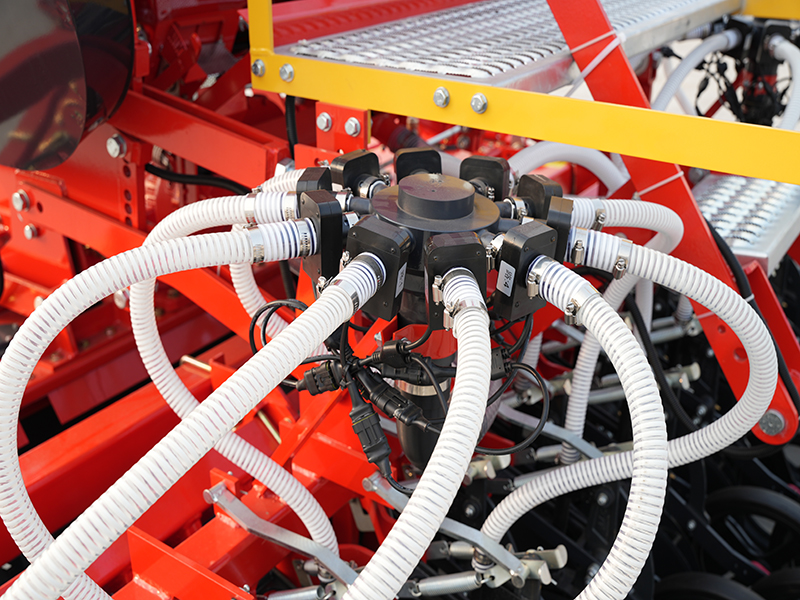

One of the most transformative developments in large-scale mowing is the use of smart sensors and automated control systems. These technologies allow machines to adapt in real time to different field conditions. Sensors detect grass density, terrain slope, and moisture levels, automatically adjusting cutting height and blade speed. This reduces manual intervention and improves consistency across large areas.

In regions like the Middle East—where land surfaces can vary between sand-based and grassy terrain—this adaptability is crucial. Automated mowing systems can prevent blade damage, reduce energy waste, and maintain uniform results without manual adjustments. For contractors managing golf courses, highways, or agricultural land, these innovations translate into less downtime, lower fuel consumption, and more consistent results.

Q: How does automation improve large-scale mowing operations?

A: Automation allows machines to operate with minimal human supervision while maintaining precision. Smart controls adjust speed, blade torque, and cutting angles based on data inputs. This not only saves time but also extends equipment lifespan by preventing overuse of mechanical parts and reducing operator fatigue.

The Role of Aerodynamics in Cutting Systems

Modern mower decks are designed using aerodynamic principles that channel airflow efficiently, lifting grass blades before cutting them for a cleaner, more even finish. By optimizing air circulation, cutting systems reduce the need for multiple passes—an essential advantage for large-scale operations where every minute and liter of fuel counts. Aerodynamic decks also reduce clumping and improve grass discharge, which is important for turf health on sports fields and golf courses.

For commercial mowing companies, aerodynamic improvements can increase productivity by up to 25%. When paired with sharp, self-balancing blades, aerodynamic systems also reduce vibration and operator fatigue, creating a smoother and more sustainable mowing process.

Sustainable Power and Cutting Performance

Sustainability has become a central focus in the development of new mowing systems. Manufacturers are investing heavily in electric and hybrid-powered cutting machines, replacing traditional diesel engines with eco-friendly alternatives that still deliver industrial-grade performance. In Europe, where emissions regulations are increasingly strict, the shift toward battery and hybrid power has accelerated.

Meanwhile, in the Middle East, solar-assisted charging stations are emerging as a practical solution for powering electric mowers in remote agricultural zones. The combination of clean energy and advanced cutting technology not only reduces operational costs but also aligns with global sustainability goals. Quieter electric systems also lower noise pollution in urban and residential areas, improving community acceptance of large-scale mowing operations.

Durability and Blade Engineering

Blade innovation remains the heart of every cutting system. Manufacturers now use heat-treated alloys and ceramic-coated edges to maintain sharpness longer. Some industrial models feature self-sharpening blades that utilize friction-generated heat to restore edge geometry during operation—reducing downtime and maintenance costs dramatically. Improved metallurgy and surface treatments extend blade life even under continuous heavy use.

Moreover, multi-directional cutting systems—which allow blades to rotate both horizontally and vertically—provide exceptional versatility. They can handle tall grass, uneven terrain, and small brush without clogging or overheating. These engineering improvements ensure high performance even under continuous, large-scale workloads.

Data-Driven Maintenance and Predictive Analytics

Modern mowing systems are now part of the smart agriculture ecosystem, where connectivity and data collection play vital roles. Built-in telematics monitor blade condition, engine temperature, and operational efficiency in real time. Cloud-based analytics platforms process this data to predict when maintenance is required—preventing unexpected breakdowns and optimizing service intervals.

Fleet operators managing dozens of machines across large farms or city landscapes can remotely track performance metrics, optimize fuel consumption, and schedule maintenance automatically. This reduces costs while maximizing uptime and ensuring that resources are deployed where they are most effective.

Q: What role does AI play in cutting system optimization?

A: Artificial Intelligence enhances performance by analyzing mowing patterns, terrain maps, and equipment data. AI can recommend optimal routes, adjust blade angles in real time, and forecast component wear—resulting in consistent efficiency and minimal waste. Over time, machine learning models improve routes and settings based on historical performance data.

Adaptability Across Different Terrains

Large-scale mowing often involves highly variable conditions—flat fields, slopes, ditches, and roadside embankments. Modern cutting systems are designed with hydraulic deck lifting, tilt sensors, and multi-zone blade control to handle such challenges seamlessly. These features ensure consistent cutting height and stability even on uneven terrain, which is particularly valuable for landscaping contractors and municipal maintenance teams.

For the Middle East’s desert-edge agricultural projects or Europe’s rolling farmlands, such adaptability is key. The result is uniform mowing that minimizes missed patches and reduces the need for secondary passes, saving time and fuel.

Environmental and Economic Benefits

Beyond performance, the latest generation of cutting systems offers tangible environmental and financial advantages. Efficient engines, regenerative braking on hybrid platforms, and aerodynamic decks can reduce fuel consumption by up to 30%. Optimized blade geometry minimizes energy waste, translating into longer operation per charge or fuel tank and lower operating expenses across large fleets.

For governments and landscaping firms focused on sustainability, adopting these systems contributes directly to carbon reduction goals and operational cost savings—a rare combination of ecological and economic value. Incentive programs and subsidies in many regions accelerate the transition to cleaner, smarter mowing equipment.

The Future of Large-Scale Mowing

Looking ahead, the future of mowing technology lies in full automation, AI-driven route planning, and advanced material science. Companies are experimenting with carbon-fiber components for lighter and more durable blades, while autonomous mowers are being developed to operate continuously with minimal supervision. Coordinated fleets of robotic mowers could work in swarms, covering large areas efficiently and safely with centralized management.

By 2030, experts predict that large-scale mowing fleets will operate fully autonomously, powered by renewable energy sources and controlled via cloud-based systems. These innovations will not only enhance productivity but also redefine what sustainable land management means in agriculture, city planning, and industrial landscaping.

Q: What industries benefit most from cutting system innovation?

A: Large-scale agriculture, municipal maintenance, golf course management, airport groundskeeping, and renewable energy site maintenance (such as solar farms) all gain efficiency, consistency, and reduced costs from advanced cutting systems. Any operation that requires regular, expansive vegetation control sees measurable benefits.

Implementation Best Practices

To realize the full potential of cutting system innovations, stakeholders should follow best practices: conduct site-specific trials, invest in operator training, deploy telematics across fleets, and choose modular systems that allow upgrades. Collaboration with equipment manufacturers ensures that blade geometry, deck design, and powertrains are optimized for local conditions and use cases.

Proper maintenance regimes, including scheduled inspections and blade balancing, extend component life and maintain cutting quality. Transitioning to electric or hybrid platforms may require changes in logistics—such as charging infrastructure—but the long-term benefits justify the investment.

Conclusion

The evolution of cutting system innovation marks a turning point for the global mowing industry. Combining smart technology, advanced materials, and sustainable power solutions, these systems deliver higher efficiency, lower costs, and improved environmental performance. Whether in the vast farmlands of North America, the arid landscapes of the Middle East, or the manicured fields of Europe, cutting system innovations are driving a smarter, cleaner, and more productive future for large-scale mowing operations.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).