Durable Tractors Deliver Reliable Power for Harsh Working Environments

In regions where farming and construction operations face extreme climates and rugged terrain, durability and reliability are not just desirable — they are essential. Durable tractors have become the backbone of modern agricultural and industrial sectors, offering consistent performance even in the harshest conditions. Whether working in the deserts of the Middle East, the rocky farmlands of Europe, or the muddy fields of Southeast Asia, these machines are engineered to deliver unrelenting power and endurance.

1. The Evolution of Durable Tractor Design

Over the past few decades, the tractor industry has witnessed a technological revolution. Manufacturers have shifted from simple mechanical models to highly engineered machines designed for efficiency, comfort, and environmental sustainability. Modern durable tractors are equipped with reinforced chassis, high-torque engines, and advanced cooling systems that allow them to operate for long hours under high stress.

China, one of the world’s largest producers of agricultural machinery, has emerged as a global supplier of durable tractors, exporting to both Western and Middle Eastern markets. These machines are not only cost-effective but also comply with stringent emission standards, making them competitive on the international stage.

2. Why Durability Matters in Extreme Conditions

In desert climates, tractors face extreme heat, dust, and uneven terrain that can challenge even the toughest machines. In contrast, European farms may deal with cold winters, wet soil, and heavy workloads during planting and harvest seasons.

A durable tractor must withstand all of these environments without compromising performance. Heavy-duty cooling systems, sealed drivetrains, and high-grade steel frames are crucial for extending operational life.

Additionally, fuel efficiency and maintenance accessibility play major roles in durability — farmers and contractors need equipment that minimizes downtime while delivering maximum output.

Q: What defines a “durable tractor”?

A: A durable tractor is engineered with robust components — from the engine block to the transmission and tires — capable of operating in extreme weather, high workloads, and tough terrains without frequent breakdowns.

3. The Role of Engine Power and Efficiency

The heart of any durable tractor lies in its engine. Manufacturers like Cummins, Perkins, and Yuchai are designing engines that combine torque with fuel economy. Tier-4 emission standards have led to innovations such as exhaust gas recirculation (EGR) and selective catalytic reduction (SCR), which reduce harmful emissions while maintaining horsepower.

For the Middle East’s arid climates, engines with high-efficiency air filters and superior heat tolerance are critical. In Europe, farmers prefer engines that balance power with environmental compliance and lower operational costs.

4. Advanced Features Enhancing Reliability

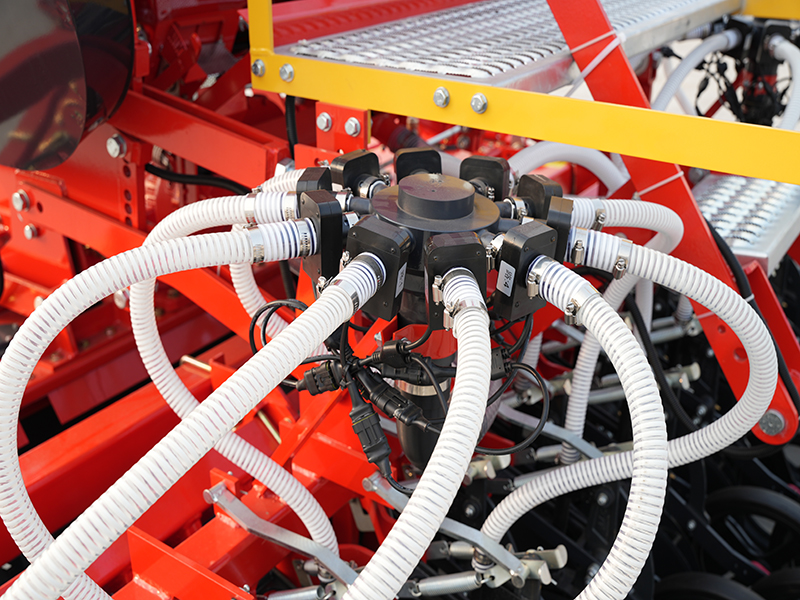

Today’s durable tractors are more than mechanical workhorses — they are intelligent, precision-driven systems. Features such as real-time telemetry, GPS guidance, and automatic load balancing help operators optimize productivity while reducing wear and tear.

Hydraulic systems with improved seals prevent leakage in dusty or wet environments. Meanwhile, ergonomic cabin designs and vibration-reduction technology enhance operator comfort, allowing for longer and safer working hours.

Q: How does technology improve tractor durability?

A: Smart sensors and telematics monitor temperature, oil pressure, and load conditions. This data helps prevent breakdowns by alerting operators to maintenance needs before failures occur.

5. Applications Beyond Agriculture

While tractors are synonymous with farming, durable models are increasingly used in construction, forestry, and disaster recovery. In the Middle East, they are vital for infrastructure projects — from grading desert roads to supporting renewable energy installations. In Africa and rural Asia, tractors are key to land development and irrigation.

The versatility of these machines lies in their ability to adapt to multiple attachments — loaders, tillers, plows, or trailers — making them indispensable for various sectors.

Q: Are durable tractors suitable for industrial or construction use?

A: Absolutely. Their reinforced frames, powerful engines, and modular compatibility allow them to handle heavy industrial equipment, making them essential in construction and logistics as well.

6. Sustainable Engineering for the Future

As global attention shifts toward sustainability, tractor manufacturers are integrating eco-friendly innovations into durable machinery. Electric-assist drivetrains, hybrid engines, and biofuel-compatible models are now entering production. These technologies not only reduce emissions but also improve long-term performance by lowering engine stress.

For example, European manufacturers are leading in hybrid systems that store braking energy, while Asian producers are developing bio-diesel-compatible engines designed for developing regions.

The goal is clear — to combine toughness with environmental responsibility, ensuring tractors remain relevant in a world demanding cleaner technology.

7. The Growing Demand in Western and Middle Eastern Markets

In Western Europe, the emphasis on sustainable farming practices and precision agriculture is driving demand for tractors that can integrate with digital platforms. Durable models with smart connectivity features help farmers optimize soil health, reduce fuel consumption, and increase yield efficiency.

In contrast, the Middle East prioritizes reliability under high temperatures and sand resistance. Durable tractors designed with advanced filtration and heat-resistant materials have become essential tools for local construction and agriculture.

Manufacturers who can meet both regions’ requirements — efficiency and endurance — are seeing explosive export growth.

8. Maintenance and Longevity: Keeping Tractors Running Strong

Even the most durable tractor requires regular maintenance to perform at its best. Preventive care — including oil changes, cooling system flushes, and filter replacements — significantly extends lifespan.

Smart maintenance platforms now allow operators to receive automatic alerts when parts need inspection. This predictive approach minimizes downtime and improves productivity, especially in remote or resource-limited areas.

Q: How long can a durable tractor last with proper maintenance?

A: With consistent servicing and the use of genuine parts, a durable tractor can operate effectively for 10–15 years or more, even under challenging workloads.

9. Economic Value and Global Market Trends

Durable tractors represent a long-term investment. Although their initial cost is higher than standard models, the lower repair frequency and fuel efficiency provide significant cost savings over time.

In global markets, particularly in Africa and the Middle East, the demand for reliable tractors is closely linked to agricultural modernization and food security initiatives. Governments and NGOs are increasingly supporting the adoption of heavy-duty machinery to enhance productivity and reduce manual labor dependency.

10. Conclusion: Power That Endures

In a world where efficiency and sustainability must coexist, durable tractors stand as symbols of engineering resilience. Whether tilling rugged farmlands, supporting construction sites, or maintaining large estates, these machines provide the dependable power that modern industries rely upon.

As technology evolves, so too will the capabilities of these mechanical giants — combining smart design, environmental responsibility, and unmatched durability to shape the future of global agriculture and industry.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).