From Plowing to Planting in Just Three Steps—China’s One-Stop Agricultural Machinery Solutions Go Global

“Made in China” is no longer just about mass production—it’s about integrated, innovative, and sustainable solutions for the world’s most pressing needs. In agriculture, where efficiency, cost-effectiveness, and sustainability are critical, Chinese manufacturers are reshaping how farms operate. Introducing the “Three-Step, One-Stop Agricultural Machinery Solution”: a streamlined system that takes farmers from plowing to planting with unprecedented ease. As global demand for food rises and labor shortages intensify, these export-ready machines are redefining the future of farming worldwide.

What Is a “Three-Step” One-Stop Agricultural Machinery Solution?

The concept combines multiple stages of field preparation and planting into a seamless workflow, using integrated or compatible machines designed to work together. Instead of sourcing different brands or dealing with mismatched implements, farmers get a single, coordinated package of equipment that covers plowing/soil preparation, seeding/planting, and optional fertilizing or irrigation setup. Chinese manufacturers bundle these steps into a one-stop package, with matching tractors, attachments, seeders, planters, and sometimes even smart monitoring systems.

Key Features and Advantages

Integrated Design: All machines and implements are designed to work together—no compatibility headaches.

Time and Labor Savings: Combining steps means fewer passes over the field, reducing fuel use, wear, and man-hours.

Precision Agriculture Ready: GPS-guided tractors, variable-rate seeding, and data tracking improve yields and reduce waste.

Cost-Effective Export Packages: Chinese factories leverage large-scale production to offer competitive prices while meeting international quality standards.

Sustainable and Environmentally Friendly: Reduced soil compaction and optimized input application support sustainable farming practices.

How Chinese Manufacturers Lead This Innovation

Complete Industrial Supply Chain: China’s manufacturing ecosystem supports everything from heavy machinery to precision components and smart sensors, enabling full-package solutions.

Customization for Global Markets: Machines can be configured for different crops, soil types, and regional regulations—from rice paddies in Southeast Asia to wheat fields in Eastern Europe.

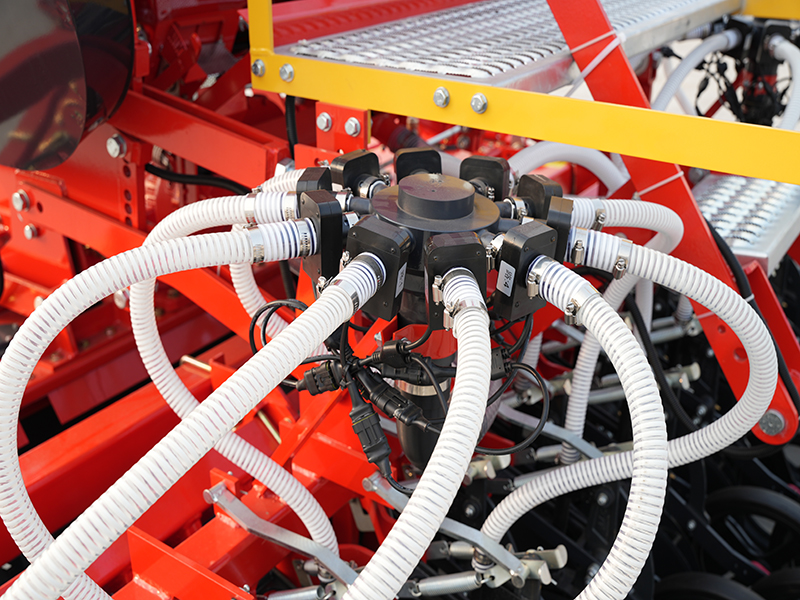

Technology Integration: Modern Chinese equipment often comes with GPS guidance, telematics, and IoT features for monitoring fuel use, acreage, and seeding rates.

Export Expertise: Manufacturers handle documentation, shipping logistics, and certifications such as CE, ISO, or local agricultural machinery approvals.

Typical Components of a One-Stop Solution

Tractors with Quick-Attach Systems – Power units tailored to local horsepower needs.

Plows and Harrows – For tillage and soil preparation.

Seed Drills or Planters – Calibrated to crop type and spacing.

Fertilizer Spreaders / Irrigation Accessories – Optional but increasingly integrated.

Smart Control Consoles – User-friendly interfaces for GPS and variable-rate applications.

Global Applications

Developing Markets: Labor scarcity in rural areas drives mechanization. One-stop packages allow small- and medium-scale farmers to leapfrog outdated methods.

Large-Scale Farms: Integrated solutions reduce downtime between operations, critical for large acreage where timing affects yield.

Government and NGO Projects: Aid programs and agricultural development initiatives can deploy turnkey machinery packages to improve food security quickly.

Why This Matters for the Future of Farming

Higher Yields with Lower Inputs – Precision reduces seed and fertilizer waste.

Faster Return on Investment – Fewer passes, less fuel, and less labor mean lower operating costs.

Easier Training and Support – One supplier provides manuals, spare parts, and service, simplifying farmer education.

Adaptability to Climate Challenges – Efficient machinery helps farmers adjust planting schedules as weather patterns shift.

Common Questions & Answers

Q1: How does a “three-step” package differ from buying machines separately?

A1: Separate machines may come from different brands with different specifications. A one-stop package ensures compatibility, integrated controls, and streamlined support.

Q2: Is Chinese-made agricultural machinery durable enough for heavy field work?

A2: Yes. Leading manufacturers use high-strength steel, quality components, and international production standards. Many models undergo field testing in multiple climates before export.

Q3: Can these machines handle different crops?

A3: Most packages are customizable. Attachments for cereals, legumes, oilseeds, or specialty crops can be swapped or adjusted to match local needs.

Q4: What about spare parts and after-sales service abroad?

A4: Chinese suppliers increasingly maintain international warehouses or partner with local distributors. They offer remote training, video support, and quick shipping of parts.

Q5: Do these systems support precision agriculture technologies?

A5: Yes. Many tractors and planters come pre-equipped or upgradeable with GPS, auto-steer, and variable-rate application systems, aligning with modern precision farming practices.

Case Example: Turning 200 Hectares from Manual to Mechanized in Weeks

A mid-sized farm in Eastern Europe recently adopted a Chinese three-step package: a 120-hp tractor, reversible plow, seed drill, and fertilizer spreader. In one season, labor hours dropped by 40%, fuel consumption fell by 25%, and yield increased by 15% due to more uniform planting depth. With local dealer support and online training, the farm was fully operational within two weeks.

Conclusion

China’s “From Plowing to Planting in Just Three Steps” one-stop agricultural machinery solution is more than a set of machines; it’s a comprehensive farming strategy. By bundling compatible equipment and integrating smart technologies, Chinese manufacturers are making modern, efficient, and sustainable farming accessible to a global audience.

For farmers, agribusinesses, and governments seeking to improve productivity and reduce costs, these export-ready packages represent a turnkey pathway to farm mechanization. As global food demand grows, such solutions will play a crucial role in feeding the world while protecting the environment.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).