Integrated Tractor Cultivator Seeder Solution Building a High Efficiency Farming Chain

Modern agriculture is evolving rapidly, and farmers across the globe—especially in emerging markets—are looking for ways to improve productivity while cutting operational costs. Traditional farming often involves multiple machines and repeated passes over the same field for tillage, soil preparation, and seeding. This approach increases fuel consumption, labor time, and soil compaction.

As a Chinese manufacturer specializing in export-oriented agricultural machinery, we have developed an integrated solution that combines a tractor, cultivator, and seeder into one cohesive system. This article explains how our “three-in-one” approach creates a high-efficiency farming chain, its advantages over conventional equipment, and answers common questions from our international customers.

1 Understanding the Integrated Tractor Cultivator Seeder System

An integrated farming machine links three traditionally separate processes—plowing, soil preparation, and sowing—into one seamless operation. The tractor provides the power and traction; the cultivator loosens and aerates the soil; and the seeder accurately plants seeds at the correct depth and spacing.

This integration means that farmers can complete essential fieldwork in a single pass. By reducing the number of machines and operators needed, it not only saves time and fuel but also improves soil health by minimizing compaction.

2 Key Benefits of the High Efficiency Farming Chain

a. Time Savings A single pass over the field dramatically cuts working hours. Farmers can prepare more land in less time, which is especially critical during narrow planting windows.

b. Reduced Operating Costs Combining functions reduces fuel consumption, maintenance expenses, and the need for multiple operators.

c. Improved Soil Health Fewer passes mean less soil disturbance and compaction, which supports better root development and moisture retention.

d. Precision Planting Integrated systems use calibrated seeders that ensure even spacing and depth, improving germination rates and yields.

e. Flexibility The solution can be adapted for different soil conditions, crop types, and farm sizes, from small family plots to large commercial fields.

3 Case Study Eastern European Farm Adopts Three-in-One Solution

A 1,200-hectare farm in Eastern Europe previously used separate tractors, cultivators, and seeders. By switching to our integrated solution, they reduced field passes by 50% and fuel consumption by 35%, while achieving more consistent seed placement. The time saved allowed them to expand cultivation without hiring additional labor, and the improved soil structure boosted yields in the following season.

4 Frequently Asked Questions

Q1 How much horsepower is needed to operate the integrated system? A: Our models range from 80 HP for small farms to 180 HP for large-scale operations. We match the equipment to your tractor or supply a complete package.

Q2 Can the system handle different seed types? A: Yes. Adjustable seed metering and interchangeable trays allow planting of cereals, legumes, oilseeds, and even specialty crops with minimal recalibration.

Q3 How difficult is maintenance compared to separate machines? A: Maintenance is simplified. With fewer engines and moving parts to service, downtime is reduced. We also provide comprehensive manuals and remote support.

Q4 Does the integrated solution work in various soil conditions? A: Our cultivator modules are adjustable for depth and tine spacing, ensuring effective tillage in clay, loam, or sandy soils. Optional attachments handle residue-heavy fields.

Q5 What about transport and storage? A: The system is designed for easy transport with foldable sections and compact dimensions. This makes it convenient to move between fields or store off-season.

5 How Integration Boosts Sustainability

Sustainability is becoming a critical factor in agriculture. By reducing the number of field passes, integrated systems lower greenhouse gas emissions, minimize soil erosion, and conserve fuel. They also help farmers comply with environmental standards and qualify for green incentives in some regions.

6 Financing and Return on Investment

While an integrated machine may have a higher upfront cost than a single implement, the return on investment is rapid. Most of our customers recover the difference within two planting seasons thanks to savings on fuel, labor, and maintenance.

7 Training and After-Sales Support

We provide training materials and on-site or remote sessions to ensure operators understand how to maximize performance. Spare parts and service centers in multiple regions ensure minimal downtime.

8 Choosing the Right Configuration

Different farms have different needs. We offer compact models for smallholder farms, medium units for mixed cropping systems, and heavy-duty models for large commercial farms. Our engineering team can also customize row spacing, seed depth, and fertilizer application to match local practices.

9 Future Trends Smart Farming Integration

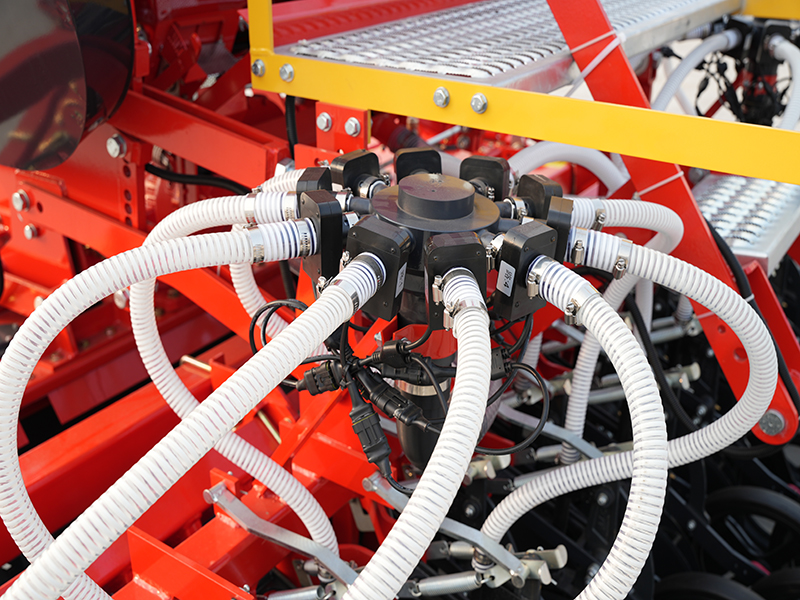

The next step is integrating sensors, GPS, and data analytics. Our upcoming models feature precision guidance, variable-rate seeding, and cloud-based performance tracking. These advancements help farmers make data-driven decisions and further improve efficiency.

10 Conclusion

Combining tractor, cultivator, and seeder into a single integrated system represents a breakthrough in modern farming. By streamlining operations, reducing costs, and improving soil and crop outcomes, it creates a true high-efficiency farming chain.

As a Chinese manufacturer committed to innovation and global service, we are proud to offer solutions that help farmers around the world achieve higher productivity and sustainability. Whether you operate a small farm or a large agribusiness, our integrated tractor-cultivator-seeder system can transform your operations and prepare you for the future of agriculture.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).